One of the most common and critical challenges in occupational safety management is when safety program is not supported.

This situation is often attributed to a poor safety culture or to leaders prioritizing production targets over safety. But one of the root causes may be a misalignment of safety risk perceptions among key stakeholders, including safety professionals, employees, and leadership.

For example, safety professionals may identify what they believe are significant risks, requiring robust controls, while employees or leaders may not recognize those same risks as serious. This disconnect can lead to a lack of enthusiasm for implementing or maintaining prescribed controls.

Alternatively, for hazards that are poorly defined or commonly misunderstood, the opposite scenario can occur. The actual risks may be negligible, yet uncertainty around exposures — such as chemicals, mold, or radiation — can lead to excessive fear or demands for additional controls.

Risk Perceptions

It is essential for safety professionals to evaluate and communicate hazards transparently and credibly, helping stakeholders align on the appropriate safety strategy — one that will be understood and supported by everyone.

That’s why one of the most important responsibilities of a safety professional is to ensure that occupational hazards and risks are accurately identified, thoroughly evaluated, and clearly communicated.

When stakeholders share a common and accurate understanding of risks, they are far more likely to support appropriate controls.

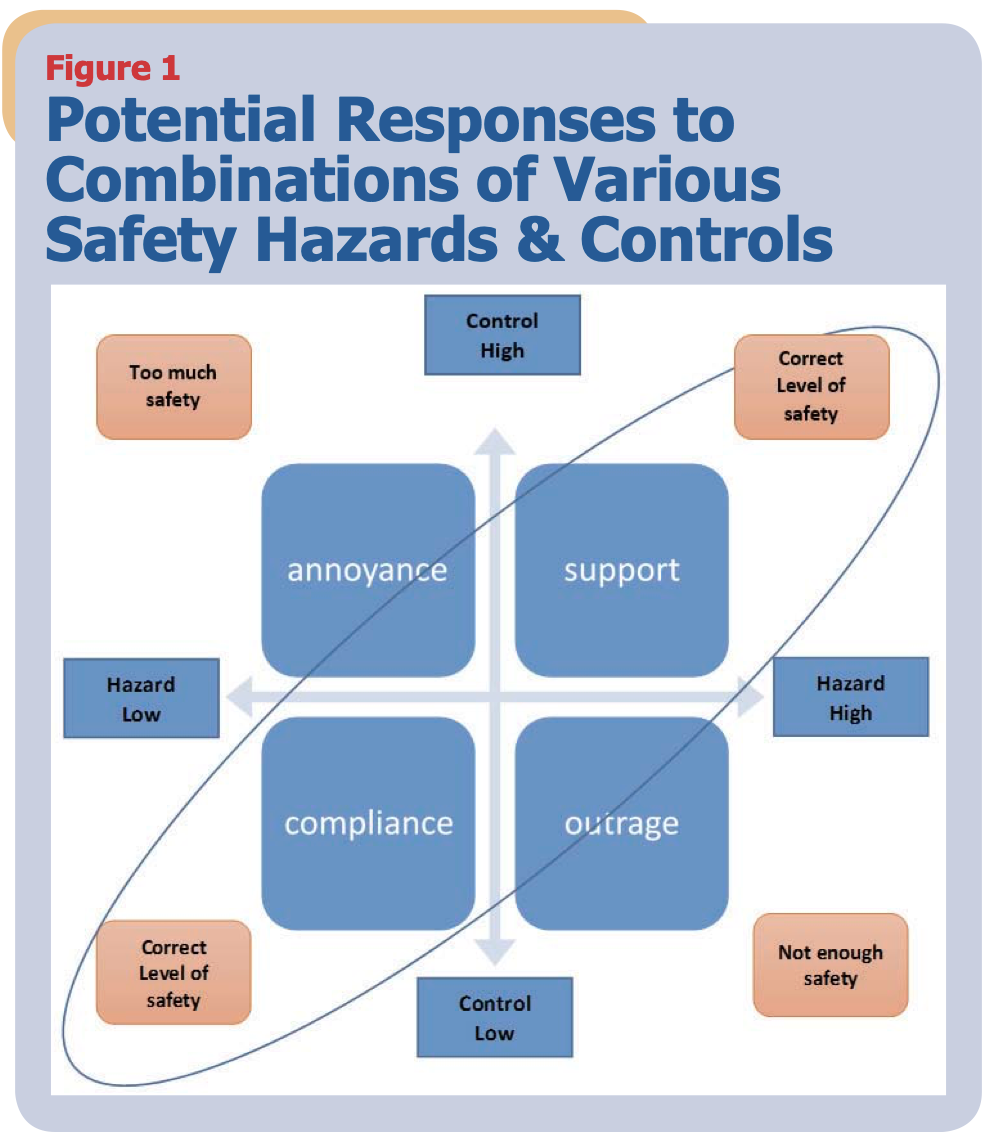

The chart below illustrates typical responses based on combinations of hazard levels (high or low) and safety controls (high or low):

· Support and Compliance reflect well-aligned situations where people recognize the risks and agree with the applied safety measures.

· Annoyance can emerge when stringent controls are applied to low hazards, creating frustration over perceived or actual safety “overkill.”

· Outrage occurs when perceived or actual hazards are high but controls are lacking, prompting demands for urgent additional corrective actions.

Objectively Evaluating Risks

A properly designed and communicated safety management system should strive to objectively assess and explain hazards and risks, align risk perception among stakeholders, and keep responses in the support and compliance range — while avoiding annoyance and outrage.

People’s natural response is to control significant risks, especially those they haven’t intentionally accepted — and it’s the safety professional’s role to make those risks clear, credible, and actionable, so they can be managed effectively by everyone involved.

V. Ivensky, Managing Risk Perceptions – Safety Programs Support Outcome, Professional Safety, 61 (08), August 2016, 44-50. https://lnkd.in/emHyWr6e